Work Project: Airtable Sync 2021

As the primary investigator in a Department of Energy project partnership, my role involved leading the development of an innovative and integrated process for the design, manufacture, and assembly of off-site panelized construction systems.

Additionally, I held the position of Director of Product Development, where I fulfilled multiple roles including Product Designer, Product Manager, and Full-Stack Engineer. Within this capacity, I was responsible for creating a comprehensive suite of tools that facilitated the entire lifecycle of designs, starting from initial proposal estimations, progressing through design production, and culminating in the management of operations on the factory floor.

These tools were specifically designed to optimize various aspects of business operations, such as identifying bulk purchase opportunities, implementing efficient inventory tracking systems, and managing the seamless transition of work orders from offsite to onsite locations. By assuming these responsibilities, I ensured that the company's products were developed and delivered with utmost efficiency and effectiveness.

Overall, my role encompassed overseeing the Department of Energy project partnership, driving the development of an integrated construction process, and spearheading the creation of a suite of tools that streamlined operations and enhanced productivity at every stage of the panelized construction system's lifecycle.

Technologies used: pyRevit, IronPython, NoCodeApi

Application

Discovery

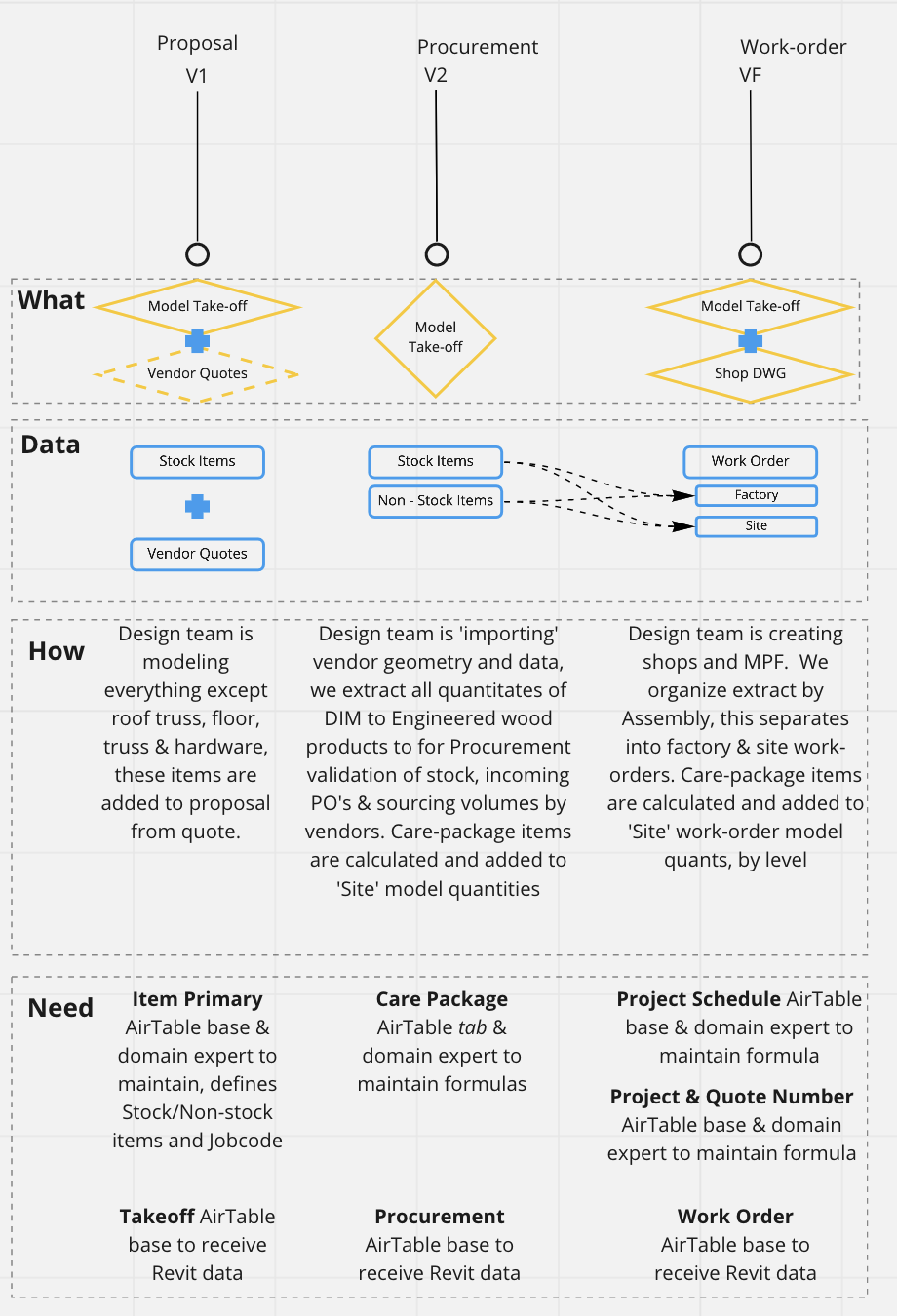

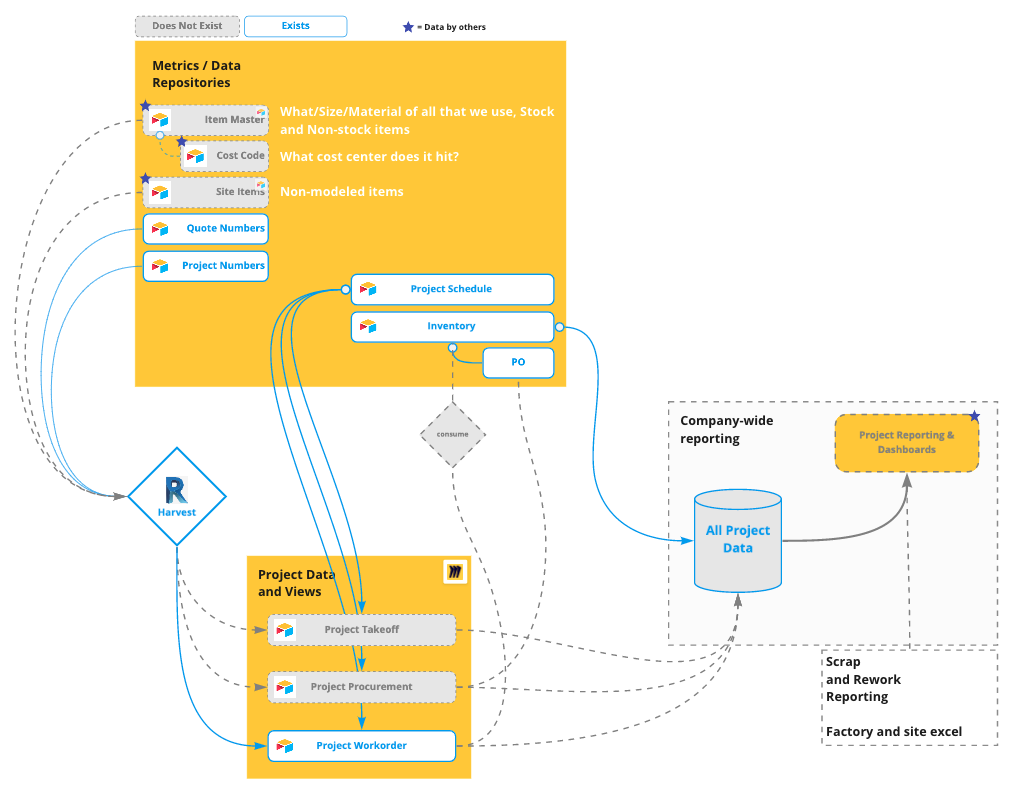

We used airtable to do POC's and for working though the build-up of information from Proposal -> Models -> Workorders.

Once that was all laid out we used multiple airtable bases to house different levels of information from models and combine it with other data sets like standard pricing, or standard site delivery items.

Tutorials

I've outlined an open source version of how to start creating these flow between models and airtable in a repo here